What is Carbon Fiber?

Carbon fiber is a material consisting of woven carbon filaments featuring high stiffness, high tensile strength, low weight, high chemical resistance, and low thermal expansion. Since its popularization in the 1970's, carbon fiber has become synonymous with innovation in almost every industry including aerospace, military, cutlery, racing, and sport. One industry that has lagged behind is musical instruments and guitars. Only recently have guitars begun being made from carbon fiber.

History of Carbon Fiber in Guitarmaking

Carbon fiber is a perfect material to apply to guitar making. In the carbon fiber manufacturing process, the finished forms start as carbon fiber cloth. Frequently, this cloth is impregnated with a heat reactive resin. The cloth is formed to molds and pressed to a rigid finished product with a combination of heat and pressure. This process is similar across many industries, but it presents a number of challenges with making a high quality guitar. Luckily, KLOS Guitars has solved all of the biggest challenges associated with making carbon fiber guitars.

KLOS Carbon Fiber Guitars

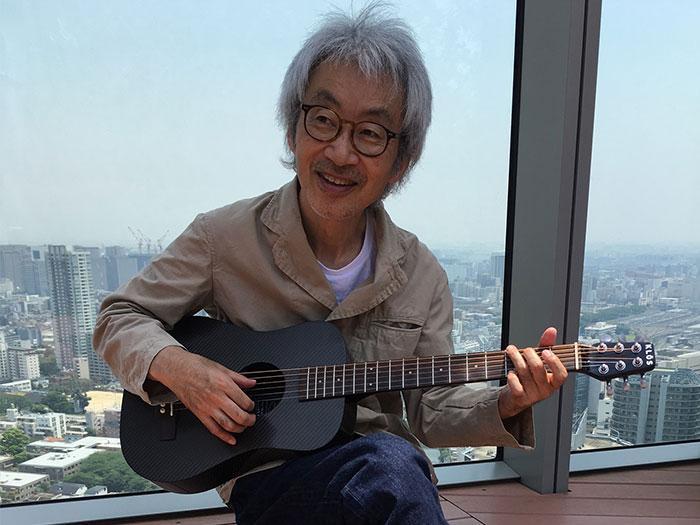

KLOS Guitars started with a mission to make an affordable, durable travel guitar out of carbon fiber. We achieved that mission and now our instruments are accompany their many owners on some of the coolest adventures you can possibly imagine.

Don't believe me? Check out this story or maybe this one.

Carbon fiber is an extremely expensive material to use for guitarmaking even when compared to expensive tone woods. KLOS Guitars feature a simple two-piece construction to enhance the sound quality and simply manufacturing.

Traditional Tone Wood for Acoustic Guitars and Instruments

Luthiers (fancy word for instrument makers) will know that the most expensive part of making an instrument be it a guitar, ukulele, or violin will always be the tone wood. Guitars can be made from just about anything from painted plywood and soft-as-butter basswood, and acoustic guitars can feature rare exotic woods from the far reaching jungles of the world.

Typically, hard and dense woods like mahogany or maple will be used for the neck. Ebony (which is even harder and denser) is frequently seen for fingerboards. Top choices for the bodies of solid body electric guitar and electric basses include alder, mahogany, ash, walnut, koa, maple, and rosewood.

Carbon Fiber vs. Wood

Many of the woods used in the manufacturing of guitars are endangered and need help with conservation. The violin industry saw a complete shut down of Penambuco wood export due too much consumption. The same fate could occur in the musical instrument industry without response and a move towards alternative carbon fiber instruments.

Carbon fiber guitars sound just as good as wood guitars while being many, many times more durable. Acoustic guitars made of wood can see massive inconsistency from one example to the next. This inconsistency can be disappointing because one instrument that your friend, teacher, or favorite pro player endorses may be excellent, but it might not be representative of those wood instruments overall. LKLOS Guitars carbon fiber instruments are extremely consistent due to material and manufacturing tolerances that are impossible to achieve with wood.

Density of Carbon Fiber

The density of carbon fiber is variable based on the thickness of the carbon fiber filaments and the amount of resin. Because carbon fiber is inherently so strong, KLOS Guitars prioritizes having the lightest carbon fiber bodies possible with the least resin for maximum acoustics, volume, projection, and tone. The KLOS Guitars soundboard is made from a laminated sandwich construction. This construction method features a foam core which maximizes reverberation. The carbon fiber top and sides can be just as thin and resonant as wood acoustic instruments, but gain massive durability.

Guitar Top Lamination and Bracing

Traditional wood instrument tops are frequently made from laminated wood. This allows for a beautiful wood to be used on the exterior that people will see while a more durable wood makes up the other laminated layer for stability.

KLOS Guitars laminated sandwich soundboard construction uses 2 layers of carbon fiber with a layer of foam in the middle to make the perfect acoustics and tone.

On wood guitars, bracing runs under the soundboard to provide support against collapse. KLOS Guitars feature reverse bracing. We cut away at our soundboard in a horseshoe shape to dial the soundboard resonance up to 11!

How Strong Is Carbon Fiber?

Super strong. Like, you will never have to worry about your guitar again strong.

How Is Carbon Fiber Fabric Made?

Carbon fiber starts as long filaments of carbon. Those carbon filaments are woven into a fabric just like any other fabric. That carbon fabric is then impregnated with resin. That resin allows the carbon fiber fabric to be formed to any shape.

Benefits of Carbon Fiber Guitars

We've already covered most of the benefits of carbon fiber guitars, but if you want to check out more read our article 10 Reasons to Consider a Carbon Fiber Guitar.

Conclusion

Carbon fiber guitars are awesome. That is honestly the conclusion of this article after laying out all the facts. Wood guitars had their place for a couple hundred years, but the times have changed. Carbon fiber is the future, but it is also now thanks to KLOS Guitars.

Are you a professional musician or influencer? Apply for our Ambassador program or contact us for more information.